Rail Bending Machine

Product Details:

- Power Rating 11 kW

- Frequency 50 Hz

- Features Sturdy frame, easy operation, precise bending

- Control System PLC controlled

- Drive Hydraulic Motor

- Lubricating System Automatic

- Noise Level 72 dB

- Click to View more

Rail Bending Machine Price And Quantity

- 100000.00 - 1000000.00 INR/Piece

- 1 Piece

Rail Bending Machine Product Specifications

- Semi Automatic

- 11 kW

- 11 kW

- Electric

- Hydraulic

- 50 Hz

- Painted

- Sturdy frame, easy operation, precise bending

- PLC controlled

- Hydraulic Motor

- 1500 kg

- Bending railway tracks and rails

- Automatic

- 120 Tons

- 72 dB

- Rail Bending Machine

- Hydraulic Bender

- Heavy Duty Steel

- 415 V

- 0.5 mm

- Air Cooling

- 3600 x 1000 x 1200 mm

- Blue

- 11 kW

Rail Bending Machine Trade Information

- 1 Piece Per Month

- 12 Week

Product Description

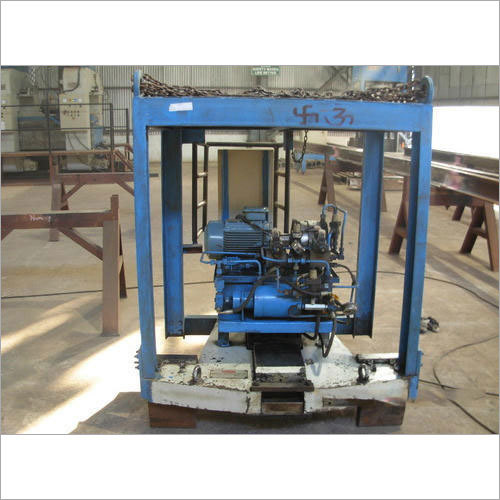

Rail Bending Machine

We manufacture, export and supply a qualitative range of Rail Bending Machine to our highly valued clients. It is used to straighten and bend railway tracks effectively and efficiently. Featured with high pressure hoses, electrical panel, low pressure gear pump, high pressure piston pump and compact hydraulic power pack, our Rail Bending Machine is easy to operate, high on performance and has a long operating life. Clients can avail it from us at highly competitive prices in the market.

Key Features:

- It is very higher performer and has a long operational life

- Considered to be very useful as it is very much convenient to operate

- Its capacity is high that is 150 tonnes and it is offered in double acting type

- The structure of this machine allows largest railway track to be easily handled

- The abutments of this machine are adjustable electro-mechanically

- Our Offered rail bending machine is specially lubricated that makes it working efficient

- Automatically guided thats why its operation is easy

- Maintenance cost of this machine is negligible that makes it more cost efficient

- This is very durable and its construction is robust

- We use nice quality of stainless steel to manufacture this machine

Technical Specifications:

|

Capacity |

Type |

Stroke |

Tank capacity |

Connected load |

Mains supply |

Voltage |

Phase |

|

150T |

Double acting |

75mm |

25 lit |

3.75 KW/5 HP |

415V,50Hz |

3-phase AC or 220V |

Single phase AC |

Precision Rail Bending for Modern Railways

Designed for railway, construction, and infrastructure sectors, this machine delivers highly accurate bends, thanks to its PLC-controlled touch screen interface and digital angle display. The heavy-duty steel frame and 120-ton pressure output ensure robust performance with every use. Its export-standard packaging and sturdy build make it ideal for both domestic and international operations.

Engineered for Operator Safety and Efficiency

Safety is at the forefront, featuring an emergency stop and overload protection. The automatic lubrication and air cooling systems help maintain optimal performance, while a low noise level ( 72 dB) contributes to a safer, more comfortable working environment. The semi-automatic operation ensures ease of use even with demanding rail profiles.

FAQs of Rail Bending Machine:

Q: How does the rail bending machine ensure precise bends in railway tracks?

A: The rail bending machine uses PLC-controlled precision and a digital angle display, allowing the operator to achieve consistent bends with an impressive accuracy of 0.5 mm. The system is semi-automatic, ensuring minimal variability during the operation.Q: What safety features are equipped in the rail bending machine for operators?

A: The machine is equipped with an emergency stop button and overload protection to safeguard operators and the equipment. Its sturdy frame and low noise emissions ( 72 dB) further enhance workplace safety.Q: When is it necessary to use a rail bending machine in railway projects?

A: A rail bending machine becomes essential when railway tracks require customized curves as part of construction or maintenance. Whether installing new rails or adjusting existing ones, the machines precise control streamlines these processes markedly.Q: Where can this rail bending machine be utilized?

A: This machine is suitable for railway construction sites, workshops involved in track maintenance, and manufacturing facilities that prepare pre-bent rails. Its sturdy design and export-standard packing support both domestic and overseas deployment.Q: What is the operation process of this hydraulic rail bending machine?

A: Operation involves positioning the rail, setting parameters on the touch screen, and initializing the PLC-controlled system. The hydraulic ram then applies up to 120 tons of pressure for a controlled bend, while lubricating and cooling systems run automatically.Q: What are the main benefits of using a PLC-controlled hydraulic rail bender?

A: Key benefits include superior accuracy, automated operation, enhanced operator safety, reduced manual labor, and the ability to handle long rails (up to 12 meters) with minimal effort.Q: How does the cooling and lubrication system contribute to the machines longevity?

A: The air cooling and automatic lubrication systems work continuously during operation, preventing overheating and reducing friction. This supports smoother performance and extends the machines service life while minimizing downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Railway Track Machinery' category

|

SIMPLETEC EQUIPMENTS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese