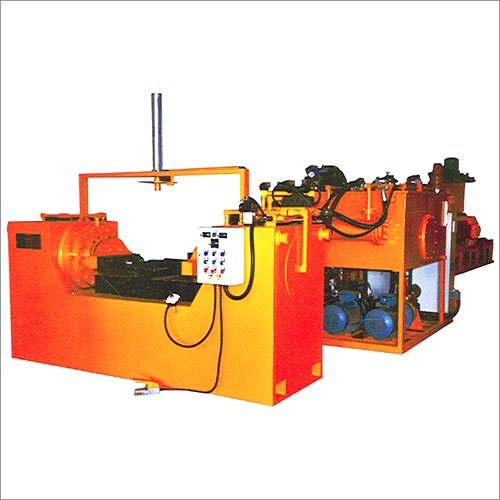

Hydraulic Track Press

100000 INR/Piece

Product Details:

- Material Mild Steel

- Power 15 HP

- Voltage 415 V AC

- Dimension (L*W*H) 3000 x 1250 x 1900 mm

- Application Assembly and disassembly of track link chains for bulldozers and excavators

- Accessories Hydraulic pump, pressure gauge, control panel, tool kit

- Click to View more

X

Hydraulic Track Press Price And Quantity

- 100000 INR/Piece

- 1 Piece

Hydraulic Track Press Product Specifications

- 3000 x 1250 x 1900 mm

- Assembly and disassembly of track link chains for bulldozers and excavators

- Mild Steel

- Hydraulic pump, pressure gauge, control panel, tool kit

- 415 V AC

- 15 HP

Hydraulic Track Press Trade Information

- Others

- 1 Piece Per Month

- 12 Week

Product Description

Hydraulic Track Press

We are a renowned supplier, exporter and manufacturer of Hydraulic Track Press to our highly valued clients. It is precisely designed for assembly/ dis- assembly of medium and large sizes of Track Chains, making use of high grade raw material and advanced machinery. 3432 KN (350T) is the maximum pressing force of each ram. It is ideal to manufacture new chains and to rebuild or re-condition. A single hand lever controlling forward and return strokes of the rams make our Hydraulic Track Press user- friendly.

Key Features -

- Automatically operated and programmable computer control unit

- High accuracy and reliability

- Efficient and high reliability

- Sturdiness in nature

- High quality of raw material used

- Low power consumption property

- Supplied at very competitive price

Technical specification:

- Capacity (each ram) : 2451 kN/250 T

- Rapid Forward : 1968 mm/min

- Press : 276 mm/min

- Return : 3780 mm/min

- Connected Load : 15 kW/20 HP

- Weight : 5300 kg.

Engineered for Maximum Performance

Crafted with a heavy-duty channel frame and mild steel construction, the Hydraulic Track Press ensures resilience during demanding operations. The 200-ton capacity and 600 mm ram stroke provide robust force for both assembling and disassembling track link chains, supporting efficient bulldozer and excavator maintenance.

Intuitive and Safe Operation

An advanced electric PLC-based control system offers streamlined, user-friendly operation with enhanced safety protocols. Operators can manage the pressing process confidently, with control features that maximize precision and reduce downtime during maintenance tasks.

Versatile Applications and Export Ready

This hydraulic track press is tailored for large-scale machine workshops and heavy equipment maintenance facilities. With standardized accessories and compliance for export, especially to regions like Ghana, it supports effortless adoption for equipment manufacturers, suppliers, and service providers.

FAQs of Hydraulic Track Press:

Q: How is the Hydraulic Track Press used for track link chain assembly and disassembly?

A: The press utilizes hydraulic force to assemble and disassemble track link chains of bulldozers and excavators. Its 200-ton capacity and 600 mm ram stroke ensure sufficient force for pressing links or removing pins, streamlining workshop operations.Q: What are the primary benefits of using this Hydraulic Track Press?

A: Key benefits include high pressing capacity, precise PLC control, enhanced operator safety, and comprehensive accessories. These features collectively improve operational productivity, reduce manual effort, and minimize machinery downtime.Q: When should the Hydraulic Track Press be used during equipment maintenance?

A: This press should be used whenever there is a need to assemble new track link chains or disassemble worn chains for repairs or replacement, typically during scheduled heavy equipment maintenance or overhaul.Q: Where is this Hydraulic Track Press most effectively utilized?

A: It is ideal for use in heavy equipment repair workshops, construction machinery service centers, and manufacturing facilities that focus on bulldozers and excavators. It is also suitable for exporters, manufacturers, and suppliers in Ghana and similar markets.Q: What process and accessories are included with the Hydraulic Track Press?

A: The pressing process is managed via a PLC-based electric control system, with power provided by a 15 HP motor. The press comes complete with a hydraulic pump, pressure gauge, control panel, and a comprehensive tool kit for seamless setup and operation.Q: How does the PLC-based control system enhance usage?

A: The Electric PLC-based control system simplifies operation by offering programmable settings, ensuring precision, safety, and efficiency in operating the press. This reduces the need for manual intervention and allows consistent, repeatable results.Q: What maintenance practices ensure optimal performance of the press?

A: Regularly check hydraulic fluid levels in the 350-litre oil tank, inspect hoses for leaks, monitor system pressure (up to 380 bar), and perform routine cleaning. Proper maintenance of the hydraulic components and control system is essential for longevity and reliable performance.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Track Press' category

|

SIMPLETEC EQUIPMENTS PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese